/ Intelligent Soft Robotic Gripping Solutions for Food and FMCG Industries

Intelligent Soft Robotic Gripping Solutions for Food and FMCG Industries

Universal Intelligent Soft Robotic Gripping Solutions

Gripping is one of the most common and natural tasks that people perform, but for robots, it is not as intuitive. To achieve human-like gripping abilities, robots need computer vision and deep learning to detect the type of objects in front of them as well as their orientation. The dexterous and adaptive gripping solutions developed by the RoPlus team can be used universally to handle a wide range of products, and can automatically decide on how best to pick and place objects with the aid of computer vision to minimize the necessity of intensive human intervention.

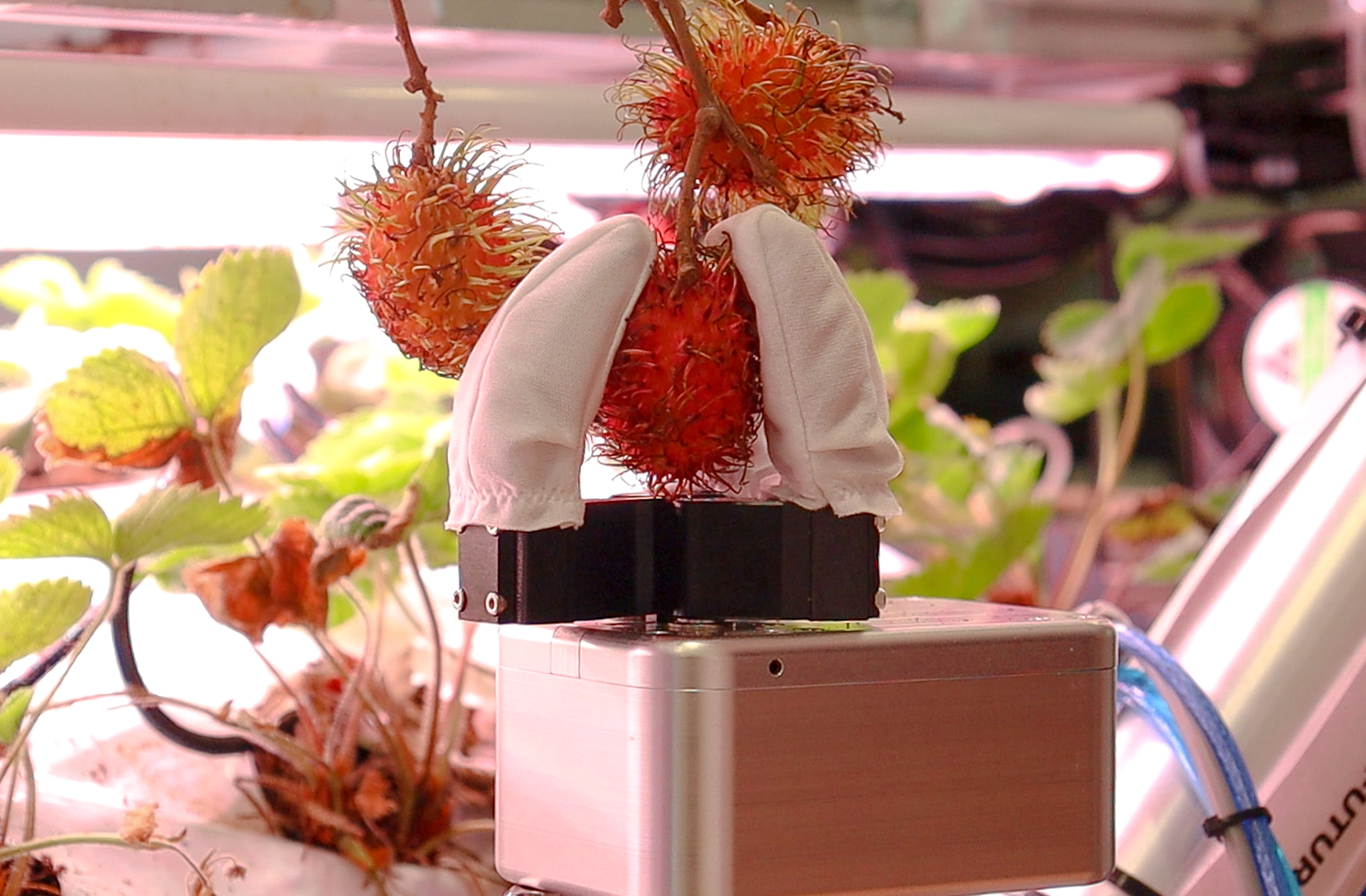

With the aim of developing robotic grippers that are as dexterous as human hands, the RoPlus team came up with hybrid robotic grippers, consisting of three or four soft fingers, which can reconfigure automatically on demand. The 3D-printed soft fingers are air-driven and equipped with a novel locking mechanism for adjustable stiffness. The 3D-printing method used to produce the soft fingers is low-cost and offers flexibility in customizing the actuator design, based on actual gripping requirements.

Different types of grippers were developed for food and consumer goods manufacturing processes. The gripper bases are reconfigurable so that they can accommodate items of various sizes. The soft rotatable gripper fingers allow delicate grasping of items of various shapes, and the embedded retractable vacuum suction cup can manoeuvre more awkwardly positioned objects such as the corner of a tote bin.

RoPlus' gripping solution is also fully customizable to adapt to specific client needs and space constraints. This approach offers a wide variety of gripping options that can handle objects of different shapes, sizes and packaging materials. The RoPlus team’s customizable technology has been deployed at People Bee Hoon Factory, a Singapore-based rice vermicelli manufacturer, for optimizing the packing of rice vermicelli packets into carton boxes.

Commenting on the company’s decision to adopt RoPlus' technology, Mr Desmond Goh, Director of People Bee Hoon Factory said, “Most of our existing staff are mature workers, so we sought to tap on new technology that can ease the workload of our existing staff, while simultaneously boosting their productivity. We selected this technology because it is able to meet our purpose, and provides flexibility for different deployments that we require.”

Other than grippers, RoPlus also develops computer vision system which can be integrated into the gripping system to command and control the configurations of the grippers automatically, based on the items detected. This can minimize human interventions during the pick-and-place tasks to fully automate the whole process.

RoPlus offers commercial partners different options of deploying the robotic gripper systems – they can be bundled together with a robotic arm, or purchased individually since the grippers can be easily mounted onto commercial robot arms for companies that already have their own.

About the RoPlus Team

The reconfigurable hybrid robotics gripping systems were created based on inspirations from the natural dexterity of the human hand by a team of entrepreneurs from the National University of Singapore (NUS). This technology is expected to impact a range of industries, involving food assembly, vertical farming and fast-moving consumer goods packaging, which will progressively automate more of their operations in the coming years.

The team comprises of Associate Professor Raye Yeow from the NUS Department of Biomedical Engineering and the NUS Advanced Robotics Centre, ex-NUS researchers Low Jin Huat, Khin Phone May, Chen Chao-Yu, Benjamin Ang and NUS alumni Han Qian Qian. The hybrid robotic grippers use soft, flexible 3D-printed fingers with a reconfigurable gripper base. The robotic innovation has now been commercialized and deployed at end-users facilities to increase productivity and efficiency of the production lines.

“An object’s shape, texture, weight and size affect how we choose to grip them. This is one of the main reasons why many industries still heavily rely on human labour to package and handle delicate items,” Assoc Prof Yeow said. “Our hybrid robotic gripper technology revolutionizes traditional pick-and-place tasks by offering advanced capabilities that allow robots to safely interact with delicate items of various shapes, sizes and stiffness, just like the human hand.”